Before painting concrete, most products recommend that you perform some concrete testing for alkalinity, as well as for water penetration and dampness.

We focus here on concrete as drywall (if really dry) is certainly good to go.

Concrete: has it been sealed?

If it has don’t just paint it without first taking the right steps to create bonding between the surface and paint. How do you know if it has? It will not absorb water well (or at all) if it has a sealer.

Johnny Cochran said it all: If it stays wet…it must be etched. Something like that.

Drop at least a ¼ cup of water on a dry slab and see if it soaks in within 30-60 seconds. If it does, it most likely has never been sealed. After you clean it in preparation for coating, do your concrete testing again to see if your absorption time changed. If it did, you did have some sealer that was partially removed by the cleaning agent.

To really be sure you remove a sealant, you may need a combination of methods: pressure washing, scrubbing with a cleaner, or even acid etching (but not if you are planning an acid-stain job) or grinding.

If your tests are inconclusive, apply a few drops of diluted muriatic acid to the surface. If it starts to bubble and fizz, then no sealer is present.

Call a pro: it will save you money in the long run.

How wet is too wet?

Short answer: All concrete is always somewhat moist. We were told by a concrete pro that concrete moisture content is rarely found to be less than 15%. Before painting or coating, concrete should be less than or equal to about 12% to 15% on your moisture meter (see below).

For comparison, indoor wood should contain no more than 12% moisture before you start. For cabinets, it’s even lower at 6% and for exterior wood up to 15%. Obviously, let the slab totally ‘dry’ after washing, back to its normal state before you apply your coating.

Concrete Testing — here we go:

-

Moisture tests

-

Alkalinity test

1. The Moisture Test for Painting Walls, Floors, and All Concrete:

People write to us all the time: ‘our new paint is peeling’. Painting wet surfaces is always a disaster. Also, the moisture in a surface and the temperature and humidity on either side of it can vary with time (seasonal, etc), so you need to test with different methods and at several different times to be sure.

Concrete floors moisture test:

Indoors or out, moisture escapes of the concrete for years after it’s set, and of course, it’s usually sitting on the earth and can wick up moisture. Use tests 2, 3, and 4: all are DIY tests. Always test a spot or several spots before coating a questionable concrete surface: it’s probably worth the cost to call in a pro.

Moisture test for walls:

If you have a problem with peeling paint, you likely have moisture in your walls. We see a lot of this and it usually ends poorly (with the expense of changing the wallboard and replacing insulation). Do the DIY testS below and if you are still not sure, call in a pro.

Four methods to test for moisture in concrete or wallboard:

You can do tests B-D by yourself, but you should ask a professional to be really sure because there are many other types of tests:

A. drilling holes for a humidity probe (looks down deeper than other tests)

B. a calcium chloride test (measures the weight before and after of a very dry powder packet of calcium hydroxide)

C. the DIY plastic sheet concrete testing

D. invasive and non-invasive meter

A. Professionals’ Way of Concrete Testing

To get a truly accurate reading or the moisture content of your concrete (all concrete is always somewhat wet), you really must call a flooring or masonry professional who will drill and use a very expensive invasive meter. Surface tests can be misleading especially in below-grade slabs.

There are some professionals talking about 15% moisture as normal, but we read lots of different numbers. So…

We contacted Wagner Moisture Meters (company website) about what to expect from a professional testing tool. They wrote, “The typical moisture content range for a reputable surface moisture meter is from 0-6.9%”.

B. Calcium Chloride Moisture Test:

There is a calcium chloride moisture test you can try. It gives you a reading, a number, that you can use in your research to see if your concrete is within the manufacturer’s standards in relation to coatings. Follow instructions exactly or have a pro do it for you. UPDATE: these tests are no longer acceptable methods of testing according to the ASTM website.

C. The Plastic Sheet Moisture Test:

Cut several pieces of air-tight 1.5 mil plastic about a yard square and use very waterproof tape (duct tape works) to tape it to the wall or floor (which should be very clean so the tape can stick and not leak). Do this in several locations. Press the tape into the grooves of the surface very firmly.

Cut several pieces of air-tight 1.5 mil plastic about a yard square and use very waterproof tape (duct tape works) to tape it to the wall or floor (which should be very clean so the tape can stick and not leak). Do this in several locations. Press the tape into the grooves of the surface very firmly.

After a 2-day wait, look to see if there is any moisture collected under the plastic. Record your observations with a camera or in writing. Wait 2 more days and repeat.

If there is any moisture trapped, you should not paint or use any coating on those surfaces until you remove the source of the moisture. Wallboards often must be replaced. You can test by ripping out a small section or two: is the insulation wet? That’s a major problem. It might be throughout your house.

D. Pin and Pinless Digital Moisture Meters

We have very little experience with these, but the maker’s instructions look very promising. General Tools products have been around a long time, so we would think this unit is best for the money.

We have very little experience with these, but the maker’s instructions look very promising. General Tools products have been around a long time, so we would think this unit is best for the money.

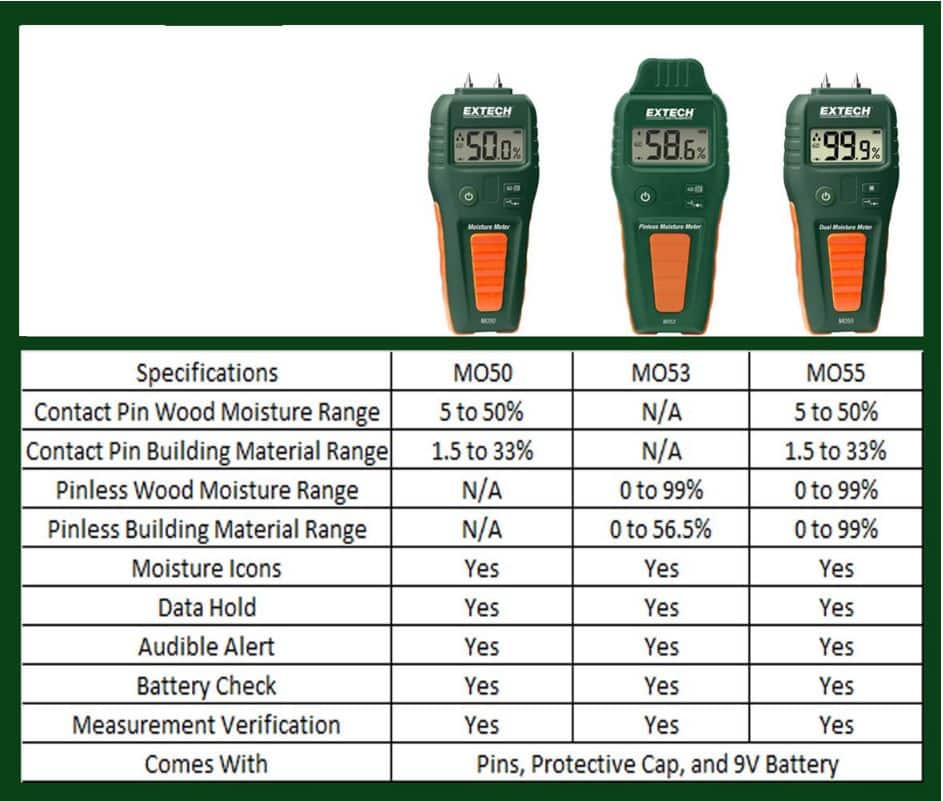

We also very much like a combination pin and pinless (Extech’s MO55 for a tad more money). The Extech company has done a good job keeping the prices down and they have a great reputation. Some other meters are unbelievably pricey.

With the Extech pinless or the pin meter you can do the following (combo meter can do both):

Pinless (uses electromagnetic field sensors, it can see not quite one inch deep, not very accurate )

- great for quick scans

- results are not a moisture reading of %

- must compare a dry area with your target area: results are only relative

- non-destructive, faster

- metal studs or screws in a wall could throw off measurements

Pinned (uses electrical resistance which gives a more accurate reading)

- gives number read-out from 0 to 100%

- leaves holes behind for the painter to fix (thank you!)

MO55 is the combo:

Best price we could find for the MO55 is here.

Moisture in Concrete Testing Conclusion

These tests are not full-proof. Every situation is different: you should really have a professional expert evaluate your structure.

If you cannot get rid of the source of the moisture, there are other ways to go: instead of paint or stain, consider tile or some sort of synthetic or moisture-resistant material: call a professional for advice.

2. Alkalinity: too much will ruin your paint job

High alkalinity causes coating failure and/or color fading. This problem is not uncommon, especially with young concrete. Concrete is known to be a highly alkaline material. When the manufacturer of concrete/cement fails to neutralize the alkalinity of the mix, you have this problem. That is why concrete testing prior to painting is so important.

Most sources will tell you to let your concrete cure for at least 30 days before coating, but we have conferred with experts who recommend waiting one year.

Masonry almost always contains lime, which is very alkaline. Until the lime has a chance to react with CO2 from the air, the alkalinity remains. This may take a full year. It can ruin an alkyd or oil product within a few months. Acrylic just takes longer to fail. Some will last longer than others but in the end, all will fail. What a mess.

Alkalinity causes the breakdown of acrylic-based coatings and even modern colorants as they react with the lime naturally in the slab.

Using paint or primer with poor alkali resistance can cause color loss and deterioration of paint film on fresh masonry: it will fail at some point.

Concrete testing: How-to test pH on concrete

- How high is too high? Benjamin Moore says that concrete should be at 7 to 8 before painting. If it is higher than 8, first prime it with the primer we recommend (below).

- To be totally certain, have a flooring/concrete professional come to your concrete to test it. They use a very expensive and sophisticated digital tool.

DIY? You can get a less accurate reading yourself with good old-fashioned pH strips. Simply clean the concrete and if old, you need to grind off a layer, as shown in this video. If you are staining your concrete, this will create an eye-sore later, so in any case, do this in an out of the way area. Drip distilled water onto the floor, wait 60 seconds and then test the water just like you did back in Doc Emmitt Brown’s chemistry class: Great Scott!

Remember, a pH of 9 is ten times more alkali than 8, and so on. Thanks, Doc.

Remember, a pH of 9 is ten times more alkali than 8, and so on. Thanks, Doc.

If your pH is above 8 for some paints or up to 12 for other paints, you need an alkali-resistant primer. Check the specks on the paint you are thinking of using with no primer, which is possible with the right paint.

For acid-based staining, it’s even more important. If you are unsure, contact your stain maker.

Here is the guide for floor professionals on pH and concrete testing.

How to solve the problem

More concrete testing: you should do repeated pH tests before you paint or stain concrete or masonry surfaces.

Allow masonry surfaces to cure for at least 30 days, and ideally for a full year, before painting. If this is not possible, you should apply a quality, alkali-resistant sealer, or latex primer, formulated to bring the pH level down for painting. The acrylic binder used resists alkali attack. This must be followed by paint.

Benjamin Moore Ultra Spec Acrylic Masonry Sealer

The best in the business in our opinion.

The best in the business in our opinion.

- alkali-resistant – up to pH-13

- 200-400 sq. ft. per gallon

- concrete, stucco, block, plaster

- Low VOC

- Follow with paint of choice

KILZ Interior/Exterior Self-Priming Masonry, Stucco and Brick Paint

Primer and paint in the same step: a lower-cost option.

Primer and paint in the same step: a lower-cost option.

- several colors, rare to find this many in a masonry paint

- alkali-resistant up to ph 12

- 250-400 Sq. ft. per gallon

We have related articles on

- painting with mold problems

- stain blocking primers

- painting over stain

- painting concrete floors

- staining concrete floors

Comments?