Every job is a bit different as your sprayer ages, as the tip ages, etc.

But you have to think about the factors that affect the thickness of the final coat:

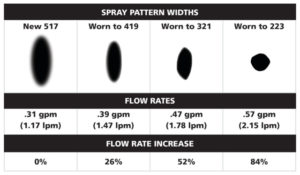

- Tip size (fan width)

- Pressure setting

- Hand speed

Key things to remember

- Overlap each stroke just enough (check coverage, up to 50% overlap)

- Hold gun perpendicular to the surface

- Pull trigger only while the gun is moving (move before and after triggering)

- Keep tip at a constant distance from the surface

- Steady hand speed

- Wear a respirator always

Remember… lower pressure = less overspray & longer tip life.

And don’t rush.

What we pros do

Interior latex is the lion’s share of what we do.

We use a .017 orifice for latex spraying.

Block fill paint would be more like .021-.025 and stains and sealers more like a .011 – .013.

Then we adapt the hand speed to every situation, and change tips at the first sign of wear.

One basic thing to remember

lower pressure = less overspray and longer tip life.

And don’t rush.

Spray job gone wrong?

- Make sure your tip / pressure combination falls within the range recommended by your sprayer

If your machine pressure is too low, you get goop, as the paint will not be atomized. Too much and it’s very wasteful.

This post needs more, obviously but those are the very basics. Want to add to it?

I see all the comments below on a daily basis.